Unpacking the True Cost of a 100% ‘Made in the USA’ Vehicle

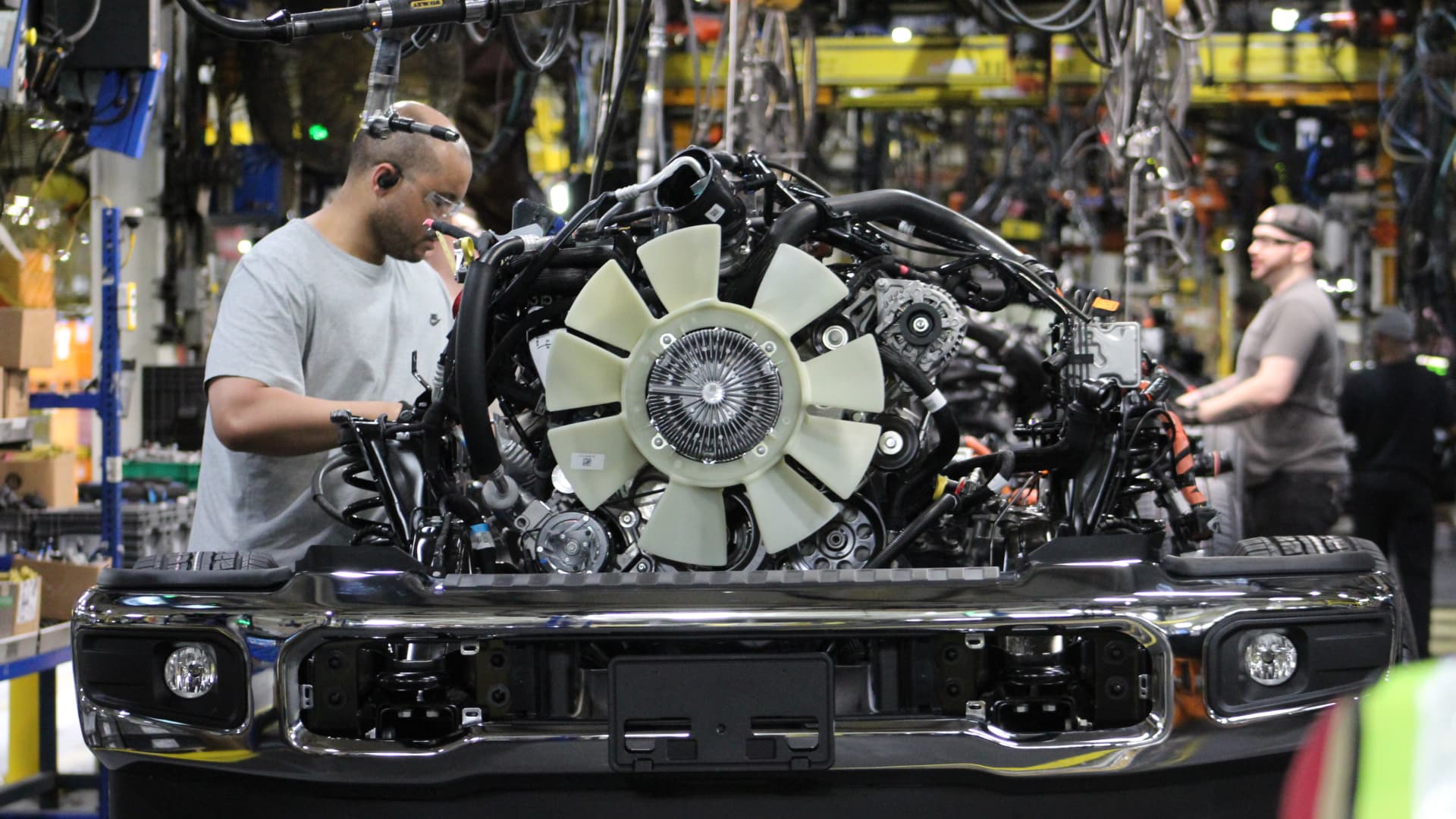

As consumer demand for American-made products surges, automakers face mounting pressure to produce vehicles entirely sourced and assembled in the U.S. But what does a 100% “Made in the USA” car really cost? From supply chain challenges to labor expenses, this investigation reveals the financial, logistical, and economic hurdles behind fully domestic auto manufacturing—and how it impacts your wallet.

The Rising Appeal of American-Made Cars

Recent surveys show 60% of U.S. car buyers prefer vehicles built domestically, citing patriotism and supply chain reliability as key motivators. However, the Automotive Policy Council notes that only 52% of the average “American” car’s components are domestically sourced. “True 100% U.S. manufacturing is a logistical Everest,” says Dr. Laura Chen, an automotive economist at MIT. “Every screw, semiconductor, and steel panel must originate stateside—and that’s prohibitively expensive without trade partnerships.”

Breaking Down the Price Premium

A 2024 study by the Center for Automotive Research estimates that a fully U.S.-made midsize sedan could cost 20-30% more than a globally sourced counterpart. Key factors include:

- Labor costs: U.S. auto workers earn 3-5x more than counterparts in Mexico or Asia.

- Material shortages: Rare earth metals for batteries and electronics often require international suppliers.

- Scale limitations: Domestic part suppliers lack the volume to match overseas cost efficiencies.

Supply Chain Realities and Trade-Offs

While the Inflation Reduction Act incentivizes domestic EV production, experts warn that isolationist policies could backfire. “Tariffs on imported parts might protect jobs but raise vehicle prices by $2,000-$5,000,” notes John Keller, a former Ford supply chain executive. For example, U.S.-made batteries cost 40% more than Chinese alternatives, per BloombergNEF data—a gap unlikely to close before 2030.

Consumer Willingness to Pay: A Divided Market

Despite the premium, 35% of buyers in a 2023 J.D. Power survey claimed they’d pay up to 15% more for a fully U.S.-made vehicle. Yet affordability remains a barrier. “Patriotism doesn’t override budget constraints for most families,” says consumer analyst Maria Delgado. Case in point: The average new car price hit $48,510 in Q1 2024, straining household finances even before “Made in USA” markups.

The Road Ahead: Can U.S. Manufacturing Scale Sustainably?

Automakers like Tesla and GM are investing billions in domestic factories, but achieving full self-reliance requires decades. “The solution isn’t all-or-nothing,” argues Chen. “Strategic partnerships—like processing foreign raw materials on U.S. soil—could balance cost and origin goals.” Meanwhile, policymakers debate tax credits for consumers who buy American, potentially offsetting price hikes.

For now, the dream of an affordable, 100% U.S.-made vehicle remains just that—a dream. But as technology and trade policies evolve, so too might the calculus. Want to support American manufacturing without breaking the bank? Research assembly locations (not just branding) and prioritize models with over 75% domestic content—the sweet spot for value and origin.

See more Business Focus Insider Team